The Weekender

Pumpkins, Pigs, Protests, & a Powerhouse

I have to give Johnny credit - he knocked it out of the park with the Halloween display.

And good news for the kids (bad for my wallet), we are headed to another pumpkin patch today!

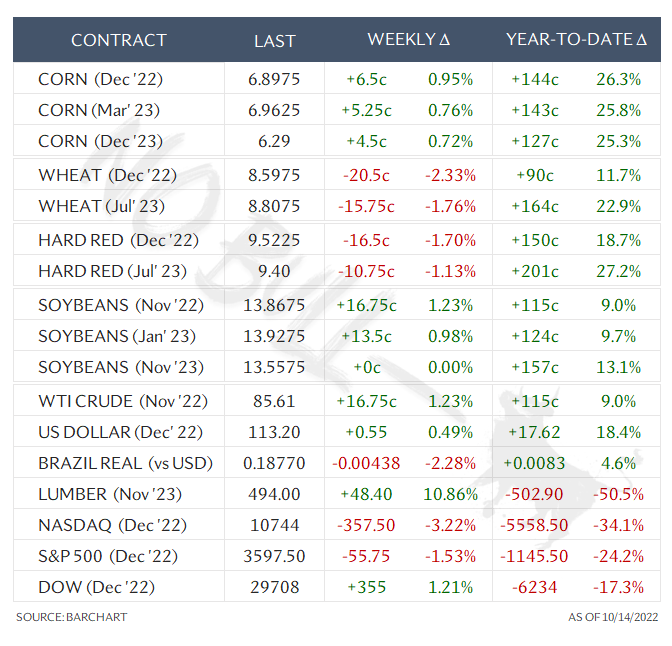

This week’s Winners & Losers

Political Piggies

California has done it again, passing a law for THEIR state that consequently effects all other 49 states in the union.

Back in 2018, California residents passed Proposition 12, an animal welfare measure that drastically changes the way eggs, pigs, and veal are produced.

While Prop 12 does not mean suppliers in all 50 states have to suddenly stop using cages for chickens or gestation crates for sows, it does mean that anyone selling eggs, pork, or veal into wholesale or retail channels in California must abide by the standards.

No big deal? Umm… think again.

The sheer size of the California market gives it substantial influence over production practices throughout the rest of the country.

California consumes 15% of the nation’s pork each year, while only producing 0.1% itself. Same goes for eggs as it is the #1 egg-consuming state in the country, but only produces <5% of national supplies.

This wild dynamic means that California’s regulatory decisions force massive changes throughout the rest of the country.

Prop 12’s ban of sow gestation crates went into effect on January 1 of this year, but is currently under review by the US Supreme Court as both the American Farm Bureau and National Pork Producers Council have argued it violates the constitution’s Commerce Clause which restricts states from regulating commerce outside their borders.

The Court heard arguments from both sides earlier this week and their resulting discussion has made the media rounds.

I find these comments very entertaining and coincidentally, Yahoo appropriately posted an article about the deliberations in their entertainment section:

Impressive that Justice Sotomayor does her own grocery shopping…

Think we will see a quick ruling? Think again.

The Court has until the end of its term to make a decision, meaning the final word might not come until the end of June 2023.

Man, our government stinks.

One last thing before we call it quits on the Prop 12 lesson today - check out the voting results by county. I will give you one guess where most of California’s agricultural production is located…

…straight up the middle and concentrated in the northern part of the state.

Follow the Leader

If you are not afraid of California’s often radical decisions, you should be.

Take their LCFS (Low Carbon Fuel Standard), for instance. Schwarzenegger’s 2007 Executive Order ~ yep, Arnold ~ will forever-change fuel standards in the United States (and soybean demand, for that matter). Such standards have now spread up the West Coast, East Coast, and Canada.

Once one state (or country) makes a bold regulatory/legislative decision, it is only a matter of time before others follow and the world turns its focus to climate change, agriculture is in the crosshairs.

A few months back the Dutch government unveiled goals to drastically reduce greenhouse gas emissions which spurred farmer protests across the Netherlands.

The mandates aim to reduce nitrogen and ammonia emissions 50% by 2030 in the second-largest agricultural exporter in the world (2nd to the US).

Dutch farmers are understandably upset as an estimated 20% of its 53,000 farms are at risk of closure due to the measure.

Fast forward to this past week and New Zealand is charting a course of their own:

I challenge you to read that headline without laughing. The bad part is - it is no laughing matter.

New Zealand’s “agricultural emissions-pricing system” is the first of its kind and stands to be the first of many to come.

Stay tuned because these are topics you will see me write about more frequently in the months ahead. Emissions regulations, renewables and newly-minted carbon markets are changing the agricultural landscape. Better hop aboard the train or you will be left behind.

Hotel California China

In typical form, the western world is headed in one direction and China is adamantly marching in the other.

One example is coal. The US is in a race to abolish its use entirely, all while China continues to smash records for coal output. Production hit a record 2,929 million tonnes in the first eight months of 2022 - the equivalent of 135 million semis of the greenhouse gas-laden stuff.

The ultimate dichotomy though, is the way the world’s largest producer and consumer of pork grows its pigs. Animal welfare groups and consumers here in the US are scrambling to make sure critters spend their days in picturesque green fields with blue skies and China… well, China is putting their pigs in high-rises.

The stories have been making the rounds for a few years now - Chinese hog hotels that will hold millions of pigs, two-dozen stories in the air.

I stumbled upon an article in Pig Progress with several pictures of one of these massive high-rise operations as it nears completion.

This two-building complex, near Wuhan in east central China, features nearly 100 acres under roof with capacity for 1.2 million slaughter pigs annually.

Each building is 26 stories high, designed to house the feed mill and other functional aspects on the first two floors.

The other 24 floors each operate like an individual farm with 1,000 sows per floor and production capacity of 25,000 slaughter pigs per year.

Can you imagine the suburban soccer mom and animal rights activist backlash here in the States?

Where we (meaning they) often get it wrong is by assuming “factory farms” are bad for the environment. In this case, that assumption couldn’t be any further from the truth.

The most interesting thing about this complex is its biogas-based waste treatment system.

From Pig Progress:

A flushing system serves to disposed of pig waste. The media sources explained how a comprehensive biogas-based waste treatment system then converts pig manure into clean energy for electricity generation and heating. Manure enters the high-temperature anaerobic fermentation system tank, which reduces the evaporation of odorous gases by more than 90%.

China’s 1.4 billion people consume more than 86 pounds of pork per capita each year. That is more than 60 million tons annually - in other words 300 truckloads AN HOUR.

Meet me in St. Louis

When you think of grain, most likely St. Louis is not the first thing to pop in your mind. In fact, it is probably last - much like the distinction St. Louis just earned as the Least Safe City in the country.

Turns out St. Louis is a grain-shipping powerhouse - the highest-capacity and most efficient inland port in the country.

At nearly 450,000 tons of cargo moved per port mile, St. Louis’ annual tonnage is 2.5 times that of runner-up Huntington, WV and 3 times larger than 3rd-place Cincinnati.

From a Corps of Engineers report:

“A stretch of the Mississippi River in and near St. Louis, Mo., has become America’s center of gravity for grain-handling for transit and export. It is so dense with grain- and fertilizer-handling facilities that can handle all transportation modes—truck, rail and barge—that it is being called “America’s Agriculture Coast” or “Ag Coast.”

St. Louis’ now 16 barge facilities can handle 160 barges a day (just call it ~10 million bushels) at full capacity - a stat no other market in the country can come close to, making its operations a critical component of US Gulf exports.

How did this happen?

St. Louis is as far north as you can get on the Mississippi River before the Lock and Dam system begins. This gives the area both a freight-cost and transit time advantage.

The benchmark tariff rate is $3.99/ton meaning that at today’s current (albeit inflated) 2000% freight, it costs $2.40 to get a bushel of soybeans from St. Louis to the Gulf.

Points north of St. Louis would pay another 40 cents to $1.30/bu more for the same trip to the Gulf as the tariff rate is higher per ton ($4.64, $5.32, or $6.19).

These advantages have left Gulf exporters leaning on St. Louis for their high-volume bushel needs.

There is somewhat of an old adage among exporters: if you are going to have a Gulf export facility, you need a terminal in St. Louis.

Bushel volumes are big and purchase margins are tiny. In many cases, margins are negative once you figure the cost to put bushels through the facility.

Wait, how does that work?

Trading, plus revenue from grades (your 10% damaged corn load set you back 30 cents per bushel but made the elevator plenty as it was blended in with 50 other loads) make up for the low initial purchase margin.

Effectively blending off moisture or poor quality is the name of the game in this high-volume market.

And when I say high, I mean high.

Fifteen years ago I left a job buying grain at a large country elevator to work for ADM. We would handle ~one million bushels of corn, beans and wheat each year. I thought that was a lot.

I began working at ADM in St. Louis and quickly learned area elevators in the area would handle one million bushels in ONE DAY, each!

Winter months were the busiest, where large terminals will dump in excess of 1,000 trucks a day. Day after day.

The numbers are quite incredible as larger facilities may handle in excess of 100 million bushels each, annually.

This picture is up close at one terminal on the Illinois side of the river.

Both of the below belts has a 60,000 bushel per hour capacity each, taking as many trucks as you can throw at it (as long as there is an empty barge at the dock).

Loadouts like the one pictured above have the capacity to handle six trains each day, the equivalent of 36 barges.

Clearly not every facility has that same setup but you get the point. Volume, volume, and more volume.

As with many things, it’s just a few more zeros.

Orchestrator of much of the expansion, Dave Jump, summed it up well speaking at a Bi-State Development meeting a few years back:

“In 1985, more than 5 percent of grain barges arriving in the New Orleans Harbors were coming from the St. Louis region, and now, that number has increased to about 30 percent. The factors that are forcing growth in the St. Louis region are not going away. There is nothing on the river like the St. Louis region.”

If you are interested in learning more about the area, this is worth a read.

I was fortunate to work in the St. Louis market for 12 years. While there were many days I wished I was not working in that cutthroat environment, it was unparalleled experience that has ultimately helped me write more effectively about market dynamics.

I say that to say this - buckle up, buttercup because if Mother Nature doesn’t give us a little water in the system, we have a very long winter ahead.

I won’t bore you with export stats today, but we will take a closer look in the Tuesday HOT TAKE as weekly sales and inspections are becoming quite telling.

(Yes, you’ll have to subscribe)

Bringing it home

I think mt favorite part about writing is being able to connect the dots.

Both literally and figuratively.

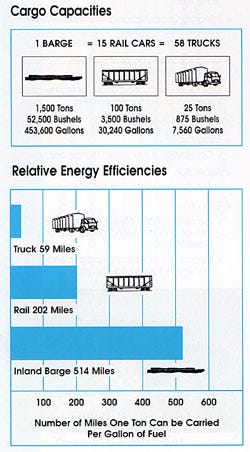

Connecting dots as in explaining a market dynamic or even simple illustrations like this one, that really put things in perspective.

My content can be quite sporadic (if you hadn’t noticed) but yet it somehow manages to come together by the end.

We are in the midst of learning a hard lesson about logistics… learning how low water can be the ultimate disruptor, handicapping US exports.

And like it or not - we (as in us in agriculture) are in a battle where it seems to be the world versus agriculture when it comes to climate change and emissions.

These things are not going away. In fact, they are becoming more intertwined with our industry with each passing day.

To bring it home today, I will leave you with this one:

Barges are the most efficient form of transportation in agriculture.

One ton of cargo can be carried more than 500 miles on one gallon of fuel via our inland waterways system - more than 2.5 times the efficiency of rail and nine times more efficient than trucks.

Thanks for coming along on today’s journey!

My website is finally up and running. You can check it out here:

NoBullAg.com

See you Tuesday!